For the 40k models, I found reference photos online and just eyeballed the details. At one point, I had access to a Leman Russ Model, and a Sentinel model. I was able to take general measurements off of them to ensure scale. I made them to look like their namesakes, but they are by no means carbon copies. I had to modify details, or come up with my own that could be printed correctly. You need to avoid overhangs greater than about 45 degrees or you need to design support structures that you plan to remove after the object is printed. Everything is printed in a layer. If you are print a lower case "r" the arm of the letter will fail without a support. If you do not model a support for it the printer will extrude the extent of it into open air. You can't just model to your hearts content and hope for the best when it prints. Care needs to be given to the medium in which you are printing. You can't have details that are thinner than the filaments printed width, because they just won't print.

I've been modeling in 3d for over 12 years. There are plenty of tutorials online for how to model in 3d.

Makerbot 3D Printers

(Pictured above)

My Makerbot Thing-o-matic kit was purchased for $1,499. (Note the price has come down to $ 1,099 for the new Mk 7) You can also see the complete Makerbot store here.

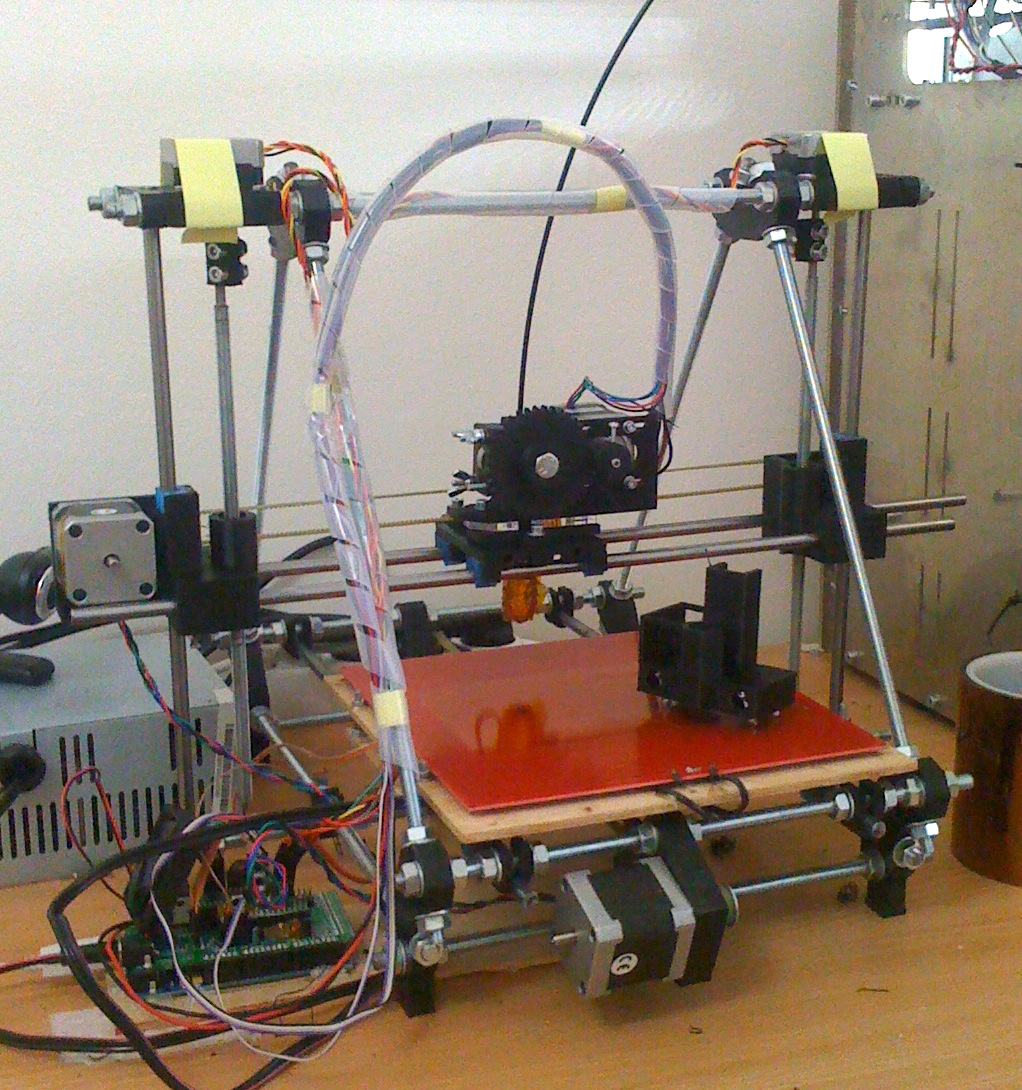

Prusa Mendel 3D Printers

Prusa Mendel is the name of an open source 3d printer. The Mendel design brought reprap into a stage where it could be built by anyone. The reason why it is important to note that it is an open source project is because the creators hold no patents. Everyone on the planet is free to create one, and the plans are openly available in the internet. Information on the reprap project can be found here: http://reprap.org/wiki/RepRap

I printed some Prusa Mendel parts for my out of state brother. He purchased $400ish worth of off the shelf parts and built a 3d printer for himself. We are working on plans to build a 3d printer that will cost us $300 in off the shelf parts. It will get me a comparable Mendel style printer. We'll see how that goes.

There are many derivatives, but they are all basically the same. 3 axis, moved by stepper motors typically,manipulating a heated extrude through a set of commands given by a computer whose end result is a physical copy of a digital design.

Going for an industrial style printer that is not FDM can lead to far greater surface accuracy and smoothness. The top of the line ones even print in full color. Those get more into the $25,000-75,000 range. One example of a company offering these printers would be zcorp: http://www.zcorp.com/en/Products/3D-Printers/spage.aspx

3 comments:

This is the future, Mini companies need to adopt asap, downliadable minis !!

We are about to enter a time when enthusiasts will be able to model, print, cast, and sell models that are superior to GW's at about the same price (or less) that GW has grown accustomed to selling it's injection-molded kits for.

GW will get it's first wake up call when the sales of it's large vehicle kits begin to drop. If they don't get their act in gear by the time the technology allows for infantry figures to be printed, then they're dead. Pure and simple.

The constant un-justified price increases are driving people who WERE loyal customers to seek other options. I spent more money than most over the last 3 years with GW. But I am sick of their price increases.

Post a Comment